A Battery Management System AKA BMS ensures the safety of the battery pack by continuously monitoring and regulating parameters like temperature & voltage.

Do you know, “What is a Battery Management System?” and “How does it work?”

Maybe you are looking to design a custom BMS system for a battery all by yourself.

In this article, we can help you with these questions and problems!

With the evolving technology, the need for the batteries is also growing at an astronomical pace. They are found everywhere, nearly in all devices from small earbuds to high-speed electric cars.

Researches are going on to make batteries as compact as possible without decreasing the efficiency.

Benefits of using BMS

- Ensure reliable battery operations

- Continuous battery health monitoring to avoid explosion

- Increases the life span of the battery

- Indicates battery level

The Battery Management System (BMS) Technology is so useful. Unfortunately, we have experienced that there is very less information available on the internet, so we have decided to round-up an article on BMS in details.

So stay tuned and read till the end.

What is Battery Management System?

Hence a BMS is a highly crucial device to ensure the safety of the battery and user.

There are many other benefits of using BMS; we will discuss them later in this article.

A BMS is an electronic board consisting of a variety of components and circuitry. After detecting a problem in operational parameters (voltage, temperature etc.) BMS triggers input to the alarm system followed by disconnecting the battery pack from the load or charger.

Building Blocks of Battery Management System

The design of the BMS is board is a bit complicated. To keep this article short and informative, we have briefly defined building blocks of the BMS.

If you want in-depth coverage of BMS board construction, refer to this article BMS Tutorial by Renesas.

As you are still here, let us discuss the BMS Building Blocks briefly,

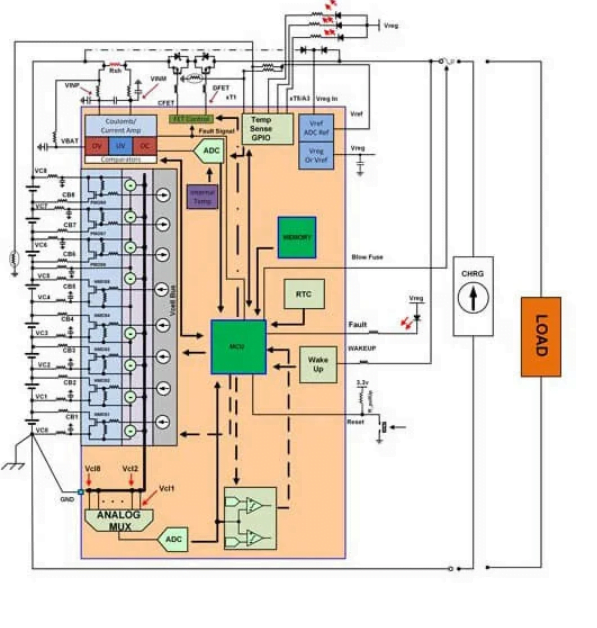

There are four main functional blocks,

- Cut-off FETs

- Fuel Gauge Monitor

- Cell voltage monitor

- Temperature Monitor

Along with this, there are few more blocks and we will describe them as well.

So without any further ado, let’s get started.

1. Cut-off FETs

A FET-driver acts as isolation between the battery and the charger. It is used to connect the high-side and low-side of the battery pack.

- High-side – Activates NMOSFET using the charge pump driver

- Low-side – Activates NMOSFET without charge pump driver

This integrated Cut-off FETs reduce the overall cost of the BMS. It is also eliminating the use of high voltage devices that could consume a large die area.

2. Fuel Gauge Monitor

This helps in keeping track of the charge entering and exiting the battery pack. The charge flowing is calculated by multiplying current and time.

Although several methods are used to measure the current flow, the most efficient and cost-effective solution is to measure the voltage of sense resistor using a 16-bit ADC with low offset and high common-mode rating.

Higher ADC is beneficial to obtain an extensive dynamic range at more speed.

3. Cell Voltage Sensors

Cell voltage monitoring can be called as a standard function of the Battery Management System. It is useful in determining the health of the battery.

All cells in a battery should operate at standard voltage levels during charging and discharging for safety and improving the lifecycle.

4. Temperature Monitoring

As technology is evolving, batteries are made to supply high currents in the meantime keeping the voltage constant.

Since a high current flow through batteries can cause sudden temperature rise and force them to explode accidentally. It needs to be avoided. For this reason, the BMS continuously monitor the temperature of the battery and regulate it to the rated value.

This feature is handy because if the temperature rises above the rated value, it will inform you to start/stop charging or discharging.

5. Other Building Blocks

Few more of the available blocks are,

- Battery Authentication – prevents the connection of BMS electronics to the third-party battery pack.

- Real-time Clock (RTC) – used in black-box application

- Memory – used in black-box application

- Daisy Chain – simplifies the connection between stacked devices

Working of Battery Management System

The working of a battery management system is determined by the complexity of the electronic components available on board.

Let we discuss the working in details by considering a standard BMS with minimal components for optimum performance.

The microcontroller of the BMS measures the cell voltage and current in real-time and based on that it switches the MOSFETs. The BMS uses only one bus for charging and discharging

Initially, both charging and discharging FETs are off so there is no current flow.

The microcontroller of the BMS senses the voltage at the input and it turns on the charging MOSFET which again starts charging the battery.

If the voltage at input pin is not present then BMS determines the load is connected and it turns on the discharging FET.

Normally two types of cell balancing are used in BMS.

- Passive cell balancing

- Active cell balancing.

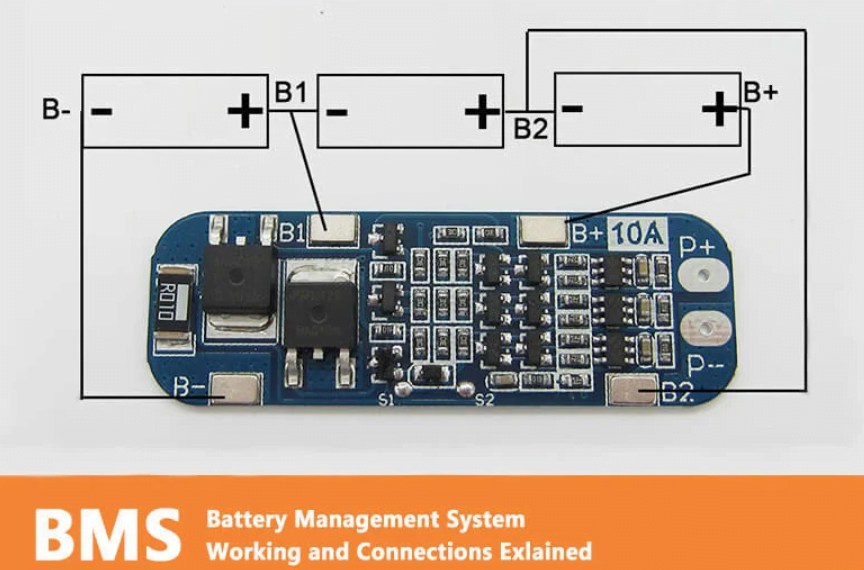

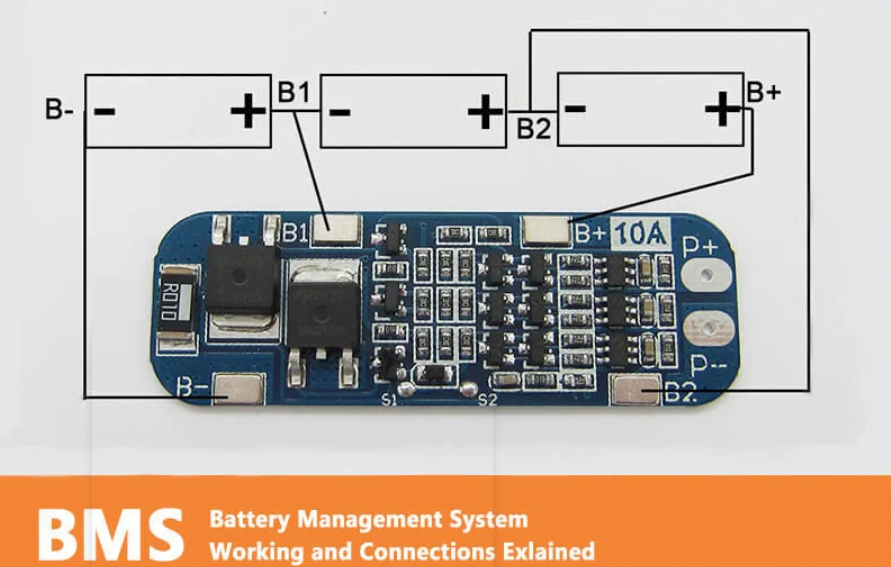

The image shows that a 3S BMS is connected with a 3-cell battery pack. Cells are connected in series.

- Storage Mode Voltage – 3.7V

- Full charge voltage – 4.2V

So the charging voltage for the three-cell battery pack is 12.6V.

The heavy gauge wires are connected to the power supply. The small wires are used as the cell balancing wires and carry less current.

A BMS has rated capacity. It measures the electric charge available and relates to the capacity.

As the capacity decreases the count of the electric charge drops.

Functions of BMS

1. Safety

A BMS does this work for you. It avoids over-charging and over-discharging of the battery pack to extend the battery life.

It also offers short-circuit protection, charging and discharging over current protection, anti-reverse charging protection etc.

Modern BMS are equipped with Bluetooth and UART communications.

2. Battery Performance Optimization

For a battery to perform at its best, it must operate somewhere between the maximum and minimum rated values, i.e. current, voltage, temperature etc.

As we learned earlier, a BMS helps batteries to operate within these critical rated values.

In case of the battery packs, it helps in maintaining equal charging and discharging of the cells. This massively improves the performance of the battery pack.

Not only performance but an efficient Battery Management System is useful in improving the life of the battery packs.

3. Health Monitoring and Diagnostics

The charge level of a battery determines the charging and discharging time. A BMS is capable of calculating and indicating the charge available in battery.

A BMS checks for the oddity in the battery parameter by comparing them with rated values. Also, it is capable of taking corrective actions to increase the health of the battery.

Most Popular BMS Boards

Also, with the right knowledge of this technology, you can design your own BMS. Yes, of course! It will take lots of time and efforts. Nevertheless it is viable in case of big battery packs.

If you have a small lithium-ion battery pack, then we can suggest few BMS that are popular in 2021.

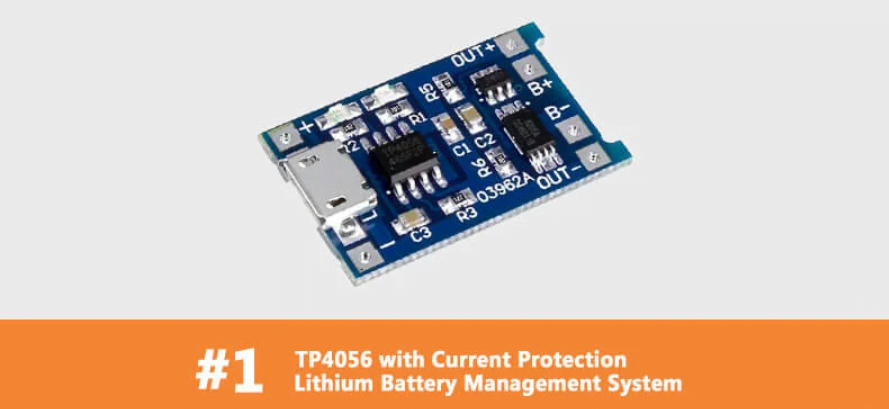

This BMS is perfect for charging a single Li-ion cell. The charge current is 1A and supplied by the TP4056 charger IC and DW01 battery protection IC.

It automatically disconnects the battery from the power supply when finished.

It is one more popular BMS for single-cell lithium-ion batteries. It comes with short circuit protection, over-current protection, over-charge and over-discharge protection.

In contrast to the above BMS boards, this board is used for 3-cell li-ion battery. You can connect this BMS with a battery of 11.1V (storage mode voltage) or 12.6 (full-charge voltage).

It offers over-charge and over-current protection.

Conclusion

We hope that you could understand the Battery Management System completely. In case of any doubts, don’t forget to comment below.

With the use of lithium-ion batteries in automobiles, the popularity and the design of a BMS is continuously improving. It is becoming increasingly important to know about this technology.

There are various types of BMS available which are categorized into 1S, 2S…. to 20S BMS. Here the word “S” stands for the number of cells.

So it means that you can use BMS with the battery packs that has upto 20 cells! At Robu, we have series of BMS available .

Leave a Reply

You must be logged in to post a comment.