SMPS High-Density Design Guide: Power Meets Efficiency

Designing a compact and efficient SMPS (Switched Mode Power Supply) can be tricky—especially for hobbyists and prototypers in India looking to pack more power into smaller spaces. But with the right approach, high-density SMPS designs are absolutely achievable, even on a tight budget.

⚙️ The Problem: Space vs. Performance

When creating high-density power supplies, the biggest challenge is managing heat and component placement. Packing too many parts too close can cause thermal buildup, EMI issues, and poor reliability. Beginner circuits often fail due to inadequate layout or component choices.

🛠️ The Solution: Smarter Layout & Quality Components

Use high-efficiency switching regulators, low ESR capacitors, and compact ferrite inductors. Space-saving surface-mount designs and proper copper pour for heat dissipation are essential. Keep switching nodes small and avoid long traces to reduce noise.

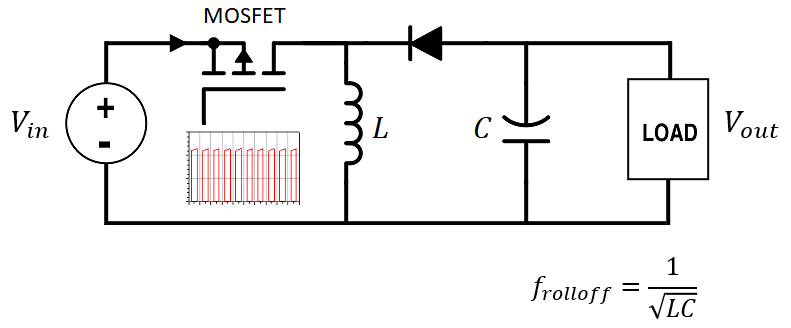

🔌 Practical Example: Building a Compact 12V to 5V SMPS

Let’s say you’re converting 12V to 5V @ 2A for a Raspberry Pi module. Using a buck converter IC like LM2596, you can shrink the design footprint using an SMD inductor and a Schottky diode. Optimizing placement helps you fit the entire SMPS in under 4 cm²!

🔢 Sample Calculation: Power Dissipation

For 85% efficiency at 10W output:

Input Power=0.8510W≈11.76W

Losses=11.76W−10W=1.76W

Plan your layout to dissipate this heat efficiently—use thermal vias or a heatsink if needed.

🛒 Product Suggestion: SMD Inductors & Schottky Diodes

Upgrade your SMPS design with SMD inductors and Schottky diodes—compact, efficient, and proudly Made in India.

👉Shop now at SmartXProKits.in.

Support our work and India’s innovation—buy from our Make in India site!