MOSFET Gate Charge Optimization for Better Efficiency in Electronics Projects

The Problem :

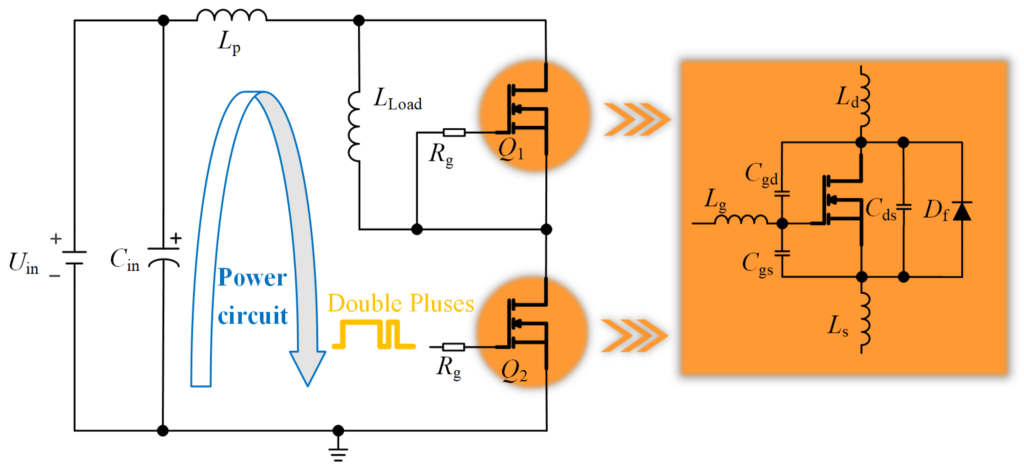

When working with MOSFETs in electronics projects, one common issue that often arises is the “gate charge” problem. In simple terms, gate charge refers to the energy required to switch the MOSFET from on to off, and vice versa. If you’re using a high-power MOSFET, this charge can cause delays, heat generation, and reduced efficiency, especially in high-speed switching circuits.

The Solution :

To optimize MOSFET gate charge, you’ll need to minimize the time it takes to charge and discharge the gate. This can be done by choosing MOSFETs with lower gate charge ratings or using gate driver circuits that are designed to supply more current to the gate faster. In some cases, adding a small resistor between the gate and ground can help by controlling the switching speed, preventing overshoot, and reducing power loss.

Practical Example :

Imagine you’re building a motor controller for a robot. The MOSFET controlling the motor needs to switch on and off rapidly to provide efficient power. If the gate charge is too high, the switching time will be slower, making the motor less responsive and causing it to heat up. By selecting a MOSFET with a lower gate charge or optimizing the gate driver, you can reduce heat, improve response time, and make the robot more efficient.

Sample Calculation :

Suppose your MOSFET has a gate charge of 20nC, and your driver can provide 1A of current.

The time to switch the gate is roughly:

t=IQ=120×10−9=20ns

A lower gate charge will reduce this time, speeding up the MOSFET’s switching process.

Product Suggestion :

If you’re working on optimizing MOSFETs in your projects, look for components like ‘MOSFET’ and ‘gate driver’ [Shop now at SmartXProKits.in]. All our products are proudly Made in India, designed for reliability and performance in your prototyping needs.