3D printing is a rapidly growing technology that has revolutionized the manufacturing industry. It has become an essential tool for producing prototypes and functional parts, and the different types of 3D printers available have made it possible to print a wide range of objects with varying levels of complexity.

In this blog post, we will explain in detail the four most popular types of 3D printers: SLA, DMLS, FDM, and SLS.

- Stereolithography (SLA) SLA is one of the earliest 3D printing technologies and is based on photopolymerization. It uses a vat of liquid resin that is cured by a UV laser, which solidifies the material layer by layer. The cured layers are lifted out of the resin vat using a platform, and the process is repeated until the object is complete.

SLA printers are best suited for producing small, detailed objects with a high level of accuracy and smooth surface finish. They are commonly used in the dental and jewelry industries.

2. Direct Metal Laser Sintering (DMLS) DMLS is a type of 3D printing that uses a laser to sinter powdered metal, such as titanium or aluminum, layer by layer. The laser fuses the metal particles together, creating a solid part.

DMLS printers are commonly used in aerospace and medical industries for producing complex metal parts with high strength and durability.

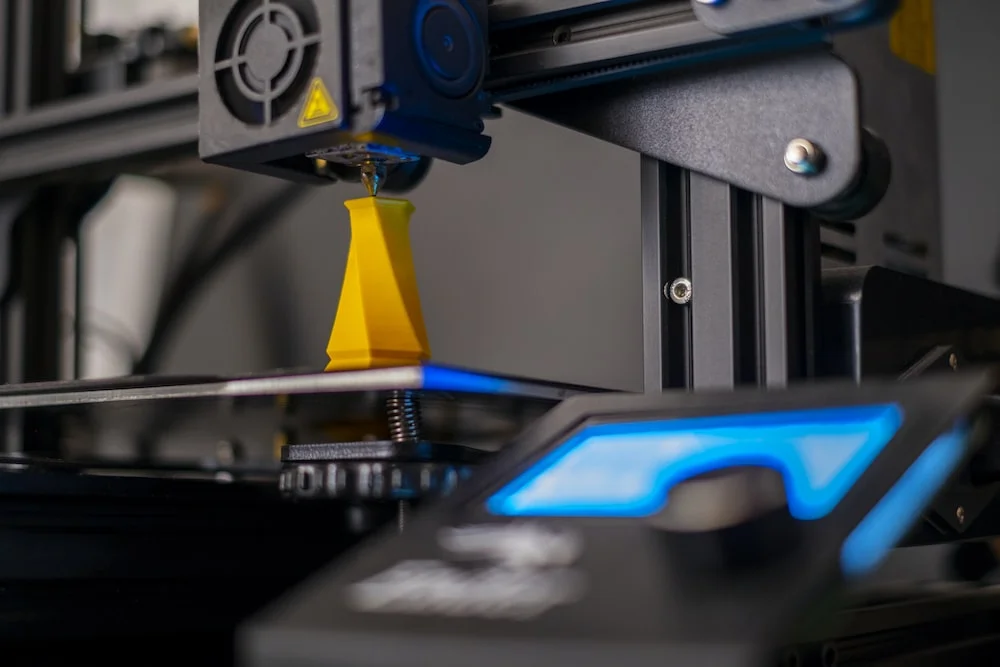

3. Fused Deposition Modeling (FDM) FDM is one of the most common types of 3D printing and is based on the extrusion of thermoplastic material through a heated nozzle. The material is melted and deposited layer by layer, creating the object.

FDM printers are ideal for producing large, functional parts with moderate accuracy and surface finish. They are widely used in prototyping and manufacturing applications, including automotive and aerospace industries.

4. Selective Laser Sintering (SLS) SLS is similar to DMLS, but instead of metal, it uses a laser to sinter powdered plastic or nylon. The laser heats the particles, causing them to fuse together layer by layer, creating a solid part.

SLS printers are best suited for producing parts with complex geometries and high strength. They are widely used in the automotive and aerospace industries for producing functional parts and prototypes.

Conclusion The choice of the right 3D printer depends on the application, material, and the desired level of accuracy, strength, and surface finish. The four types of 3D printers discussed in this blog post, SLA, DMLS, FDM, and SLS, offer a wide range of options for 3D printing applications, from small detailed objects to large functional parts.

Written by kanchan kan

- Industrial Automation141141 products

- Cooling Fan44 products

- Indicators1111 products

- Plastic Casing66 products

- Sensor2323 products

- Sleeve and cables55 products

- SMPS88 products

- Solid State Relay Module22 products

- Switches1818 products

- Temprature Sensor11 product

- 3D Printing187187 products

- 3D printing116116 products

- Combination Kit4747 products

- Electronic737737 products

- Audio55 products

- Battery/Charger Accessories2828 products

- Capacitors6363 products

- Connector4646 products

- cooling fan11 product

- Diode3535 products

- Displays1212 products

- IC and Chips6464 products

- IOT and Wireless99 products

- Leds2424 products

- Microcontrollers55 products

- Modules/Shield7575 products

- MOSFET / IGBT1414 products

- Power Supply2525 products

- Resistors128128 products

- Sensors5959 products

- SMD2828 products

- Switches1414 products

- Transistors6767 products

- Wire and Cables1212 products

- Hardware3232 products

- Hand Tools1414 products

- Hardware Accessories1414 products

- Printing22 products

- RC Plane and Drone99 products

- Robotic147147 products

- BO Motors1313 products

- General Purpose DC Motors2929 products

- Motor Drivers88 products

- Robotic Wheels & Tyres1414 products

- Servo Motor2727 products

- Stepper Motors88 products

- Synchronous Motor11 product

- Science Fair Project7070 products

- Final Year Ready Project Kit11 product

- STEM KIT2222 products

- E Books88 products

Leave a Reply

You must be logged in to post a comment.