SMPS Component Stress Reduction Tips

⚠️ The Problem: Component Stress in SMPS Circuits

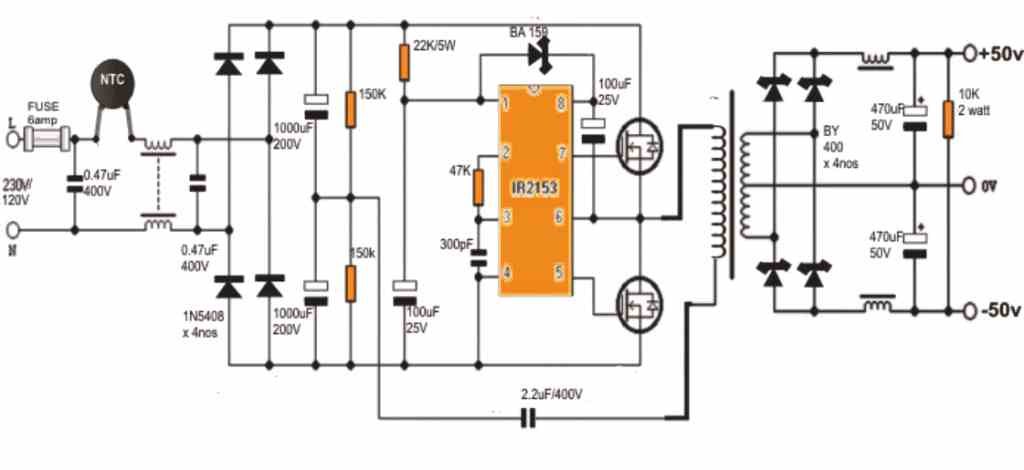

In SMPS (Switched-Mode Power Supplies), components like MOSFETs, inductors, and capacitors often face high-frequency switching and power surges. Without proper stress control, this leads to overheating, reduced efficiency, or even early component failure—especially in DIY or compact power projects.

🔧 The Solution: Reduce Electrical Stress with Smart Design

To minimize stress, use snubber circuits, gate resistors, and choose components rated above your expected peak voltages and currents. Soft-start features and adequate heat sinking also go a long way in preventing shock-load damage.

💡 Practical Example: Building a Compact 12V SMPS for a Router Backup

If you’re prototyping a backup power supply for a 12V Wi-Fi router, continuous load plus switching can overheat the MOSFET. Adding a 10Ω gate resistor can slow down the MOSFET’s switching speed slightly, reducing voltage spikes and stress.

🧮 Sample Calculation: Gate Resistor Power Dissipation

Say a MOSFET gate draws 50nC per switch at 100kHz.

Power = V × Q × f = 12V × 50nC × 100kHz = 60mW (approx)

Using a 0.125W resistor is sufficient and safe here.

🛍️ Product Suggestion:

Protect your circuits using high-quality gate resistors and MOSFETs.

🔗 Shop Resistor – Made in India

Shop now at SmartXProKits.in

Support our work and India’s innovation—buy from our Make in India site!