Top Mistakes Buyers Make When Choosing a Radiography Film Viewer

Radiography testing (RT) is one of the most critical techniques in NDT (Non-Destructive Testing) for weld inspection. But the accuracy of defect detection doesn’t depend only on the quality of the film—it also relies heavily on the film viewer being used.

Unfortunately, many buyers in India make avoidable mistakes when selecting a radiography film viewer. These errors not only reduce inspection accuracy but also lead to higher costs, project delays, and safety risks.

Here are the top mistakes to avoid when choosing a radiography film viewer.

1. Ignoring Density Rating

One of the most common mistakes is overlooking the film density rating of the viewer.

NDT weld radiographs often require evaluation up to 4.0 D density.

Viewers with lower ratings may not reveal fine cracks or porosity.

Always check the optical density capability before buying.

👉 Tip: For industrial weld inspections, never settle for a viewer rated below 4.0 D.

2. Buying Medical Viewers Instead of NDT Models

Another major mistake is purchasing medical X-ray film viewers instead of NDT-specific models.

Medical viewers are designed for body imaging, not dense weld films.

They lack the brightness and uniformity required for industrial radiographs.

Using them can result in missed defects and false interpretations.

👉 Tip: Always confirm the viewer is designed for NDT applications, not medical use.

3. Neglecting Portability

For pipeline inspections and remote field projects, portability is key. Many buyers only focus on lab models and regret not having a portable film viewer.

Compact models like 2.5″×8″ dual power viewers are ideal for on-site work.

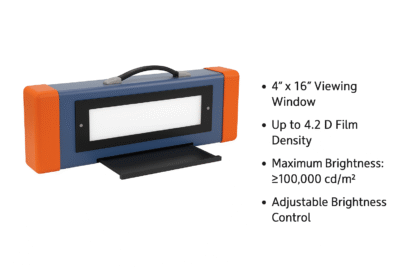

Standard 4″×16″ models are best for lab and shop-floor environments.

A balanced setup may require both types, depending on the application.

👉 Tip: Match your purchase to your inspection environment—field, lab, or both.

4. Overlooking Brightness Control

Not all inspections require the same light intensity. Without adjustable brightness control, inspectors may face eye strain or struggle with varying film densities.

👉 Tip: Look for models with smooth brightness adjustment for flexibility and comfort.

5. Choosing on Price Alone

Cheaper viewers may seem attractive but often lack brightness, durability, or reliability. Long-term, they cost more in rework, downtime, and replacements.

👉 Tip: Focus on specifications and reliability, not just cost.

Conclusion

Choosing the right NDT radiography film viewer is crucial for accurate weld inspection. Avoid mistakes like ignoring density ratings, buying medical viewers, or neglecting portability. Instead, invest in a high-brightness, 4.0 D-rated, NDT-specific viewer that suits your inspection environment.

By making an informed decision, you’ll ensure better defect detection, fewer errors, and higher reliability in your inspection processes.

For industries where weld quality is non-negotiable, investing in LED film viewers translates into safer operations, fewer reworks, and stronger compliance with standards.

👉 Call to Action

Looking for the best radiography film viewer in India? Explore our range of NDT-specific LED film viewers designed for weld inspections in labs and field environments. Shop Now at SmartXprokits