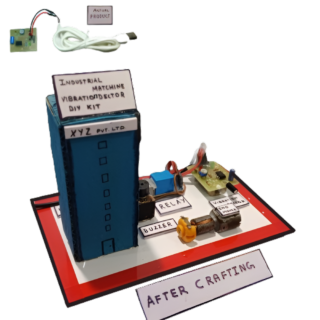

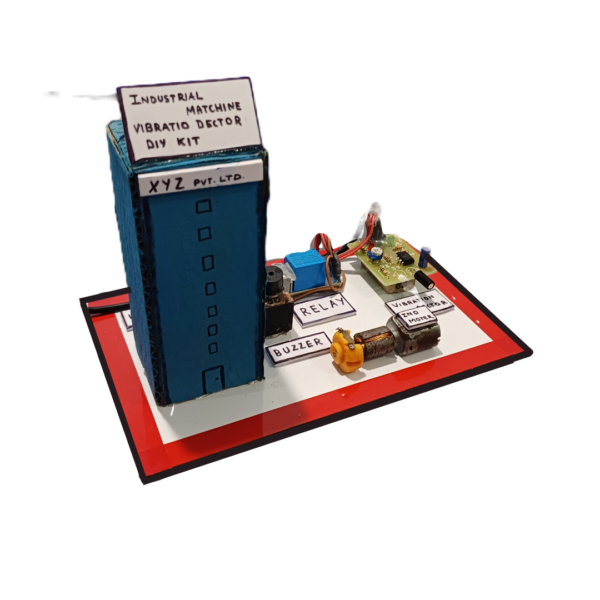

Induction Motor Vibration Detection DIY Experiments Science Project Model STEM KIT (Assembled), 100% Tested

Original price was: ₹1,024.00.₹599.00Current price is: ₹599.00. + GST

- Induction Motor Vibration Detection assembled kit, 100% tested for reliability.

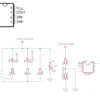

- Includes full documentation: circuit diagrams, PCB layout, and testing documents.

- YouTube videos available for easy setup and understanding.

- https://www.youtube.com/watch?v=hPgNWCX23Sg

- 100% support on working days (11 AM – 6 PM). Email: Smartxbrains@gmail.com.

- Fastest delivery across India, perfect for various electronics projects.

99 in stock

99 in stock

96 in stock

96 in stock

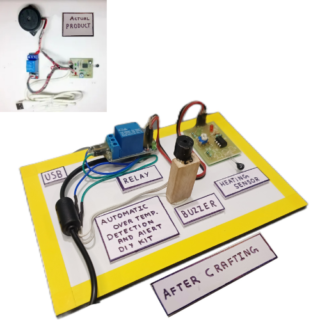

Please Note we are only providing kit we marked as ACTUAL PRODUCT, project shown customer needs to do at there own we just provide reference.

Abstract:

The Induction Motor Vibration Detection circuit is built using a piezoelectric sensor and a comparator IC LM393. The piezoelectric sensor detects vibrations, while the LM393 acts as a comparator. In the absence of vibration, the piezoelectric sensor doesn’t conduct, and the LED stays off. When vibrations are detected, the sensor conducts and the LED glows, indicating the presence of vibrations.

Application of the Circuit:

This circuit eliminates the need for expensive or complex vibration sensors by using readily available piezoelectric sensors. The Induction Motor Vibration Detection circuit efficiently activates an LED to indicate vibration, making it ideal for motor diagnostics and automation projects.

Why This Particular Circuit:

Piezoelectric sensors operate efficiently with DC voltages of 5V, which is easily achievable with a DC power supply cable.

Explained Working of the Circuit:

The piezoelectric sensor converts vibrations into electrical signals, which the LM393 comparator interprets to activate the LED in the presence of vibration. The circuit ensures simple operation and reliable performance.

How to Build:

- Thoroughly read the manual and study the circuit diagram and PCB layout.

- Solder components as per the PCB layout, ensuring correct positioning and polarity.

- Use IC sockets for easy IC replacement during troubleshooting.

- Start from the leftmost corner of the PCB and solder components sequentially.

- Pay close attention to sensitive components like diodes and capacitors.

Testing the Kit:

After assembly, connect a 5V DC power source. Apply vibration to the piezoelectric sensor to test. The LED should glow when vibrations are detected. Adjust the R2 variable resistor to set the desired vibration detection intensity.

ICs Used:

- LM393: A dual comparator IC commonly used for vibration detection circuits.

Part List:

- Semiconductors: LM393 (U1), 8-pin base

- Resistors: R2 – 10k Ohm (variable), R3 – 1k Ohm, R4 – 1k Ohm, R5 – 10k Ohm, R6 – 10k Ohm

- Capacitor: C1 – 1uF

- Miscellaneous:

- Piezoelectric Sensor (D4)

- Red LED (D1)

- Green LED (D2)

- 5V USB Cable

- PCB

Key Applications:

Used in motor diagnostics, automation, robotics, and educational projects. Optimized for performance in India-specific environments.

Keywords:

- Induction Motor Vibration Detection DIY KIT

- STEM KIT Assembled

- 100% Tested

- electronics components India

- buy online Induction Motor Vibration Detection KIT

- electronic supplies India

Zohar (verified owner) –

Good techinical knowledge

Harsh (verified owner) –

Best cost electronic components in India

Devendra (verified owner) –

Good service.

Rohit (verified owner) –

Less cost than other websites

Jayen (verified owner) –

The product is firmly packed.

Viral (verified owner) –

Good support and recommended

Akshay (verified owner) –

I got my project done with these components Great Support

Harsh (verified owner) –

Online best cost electronic components

Priya (verified owner) –

Best cost electronic components in India

Sneha (verified owner) –

Good support and recommended

Harsh (verified owner) –

Good service.

Paaji (verified owner) –

Good support and recommended

Ayush (verified owner) –

Less cost than other websites

Priya (verified owner) –

Very fast delivery.

Lokesh (verified owner) –

Good Kit

Mayur (verified owner) –

Good support and recommended

Harsh (verified owner) –

Best cost electronic components in India

Komal (verified owner) –

Good Kit

Prakash (verified owner) –

Best Science project

Vivek (verified owner) –

Best cost electronic components in India

Akshay (verified owner) –

The product is firmly packed.

Komal (verified owner) –

Drone parts i ordered and found ok

Viral (verified owner) –

Very well worth the money.

Paaji (verified owner) –

I got my project done with these components Great Support

Ayush (verified owner) –

Best Science project

Roma (verified owner) –

Best Science project

Vivek (verified owner) –

Very fast delivery.