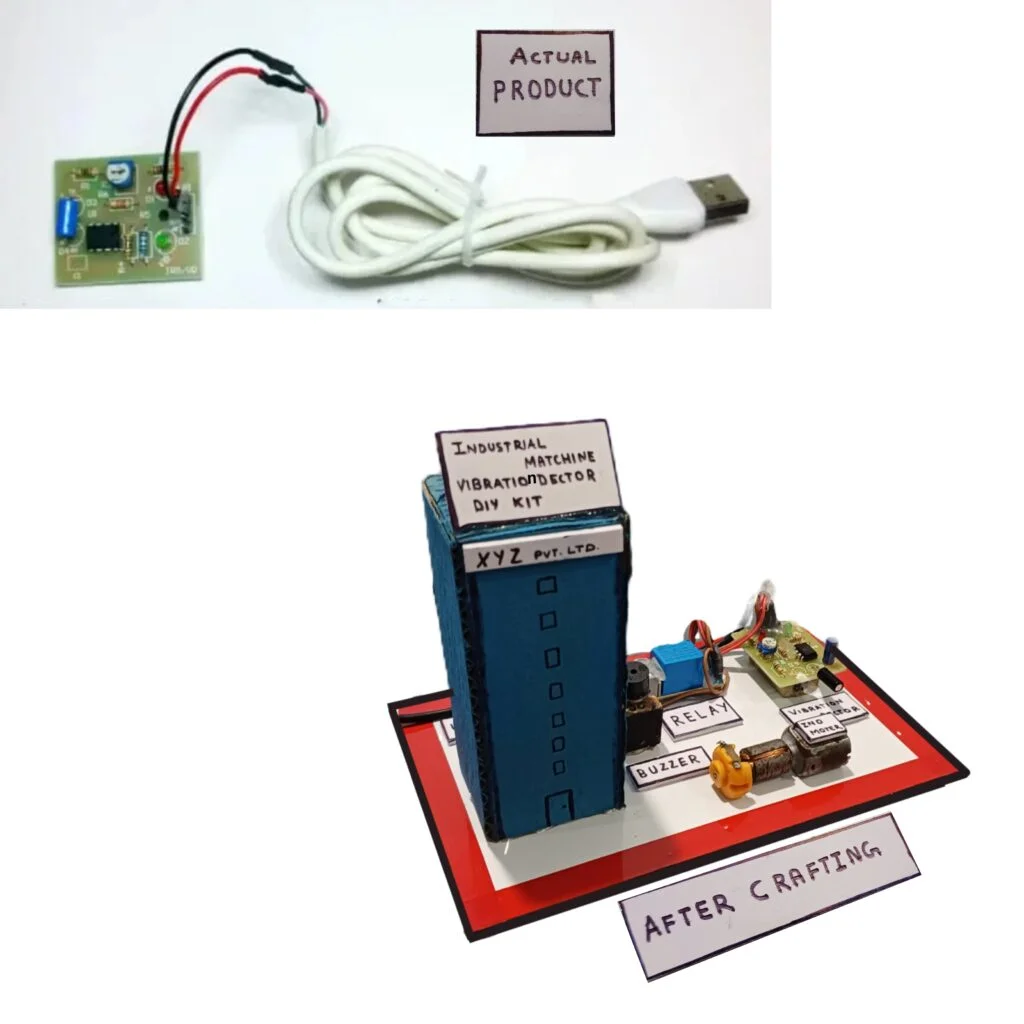

When it comes to monitoring motor vibrations, you need a solution that’s both accurate and easy to implement. The Induction Motor Vibration Detection STEM Kit offers just that—a practical, affordable, and effective way to track motor performance. Let’s walk through a few real-world scenarios that show how this kit can solve your vibration monitoring challenges.

Case Study 1: Motor Diagnostics for Small-Scale Manufacturing Imagine you’re working in a small-scale manufacturing environment where motors play a critical role in production. Vibration is a common cause of motor failure, and detecting issues early is essential for reducing downtime. With the Induction Motor Vibration Detection Kit, you can easily monitor motor vibrations. The piezoelectric sensor sends a signal to the LM393 comparator, which triggers the LED to alert you to any vibrations above a set threshold.

Case Study 2: Educational Project for STEM Students Let’s say you’re an educator teaching an electronics class. The Induction Motor Vibration Detection STEM Kit offers a fantastic hands-on project to help students understand the principles of vibration detection and motor diagnostics. By following the instructions and assembling the components, students gain practical experience with piezoelectric sensors, comparator ICs, and motor maintenance—all while engaging in an enjoyable learning experience.

How Does It Work?

- Step 1: Assemble the components as per the provided instructions, ensuring each component is properly soldered.

- Step 2: Connect the 5V DC power source to the PCB.

- Step 3: Apply vibrations to the piezoelectric sensor. The sensor converts vibrations into electrical signals.

- Step 4: The LM393 comparator interprets the signals, and if the vibrations exceed a certain threshold, the LED lights up, signaling an issue with the motor.

Why This Kit is the Right Choice:

- Cost-Effective: Traditional vibration sensors can be expensive and complex, whereas this kit offers a simple solution for a fraction of the price.

- Reliability: The LM393 comparator ensures that vibrations are accurately detected, providing consistent results.

- Easy to Use: With detailed instructions and a straightforward design, the kit is perfect for both beginners and experienced electronics enthusiasts.

The Induction Motor Vibration Detection STEM Kit is not just a project—it’s a practical solution for real-world challenges. Whether you’re diagnosing motors, teaching students, or building automation systems, this kit has everything you need.

Ready to Take Action?

Don’t miss out on the opportunity to improve your vibration detection process. Order now and get started with your own Induction Motor Vibration Detection project today!

Written by smartxbrains

- Industrial Automation141141 products

- Cooling Fan44 products

- Indicators1111 products

- Plastic Casing66 products

- Sensor2323 products

- Sleeve and cables55 products

- SMPS88 products

- Solid State Relay Module22 products

- Switches1818 products

- Temprature Sensor11 product

- 3D Printing180180 products

- 3D printing110110 products

- Combination Kit4747 products

- Electronic743743 products

- Audio55 products

- Battery/Charger Accessories2828 products

- Capacitors6464 products

- Connector4646 products

- cooling fan11 product

- Diode3535 products

- Displays1212 products

- IC and Chips6565 products

- IOT and Wireless99 products

- Leds2424 products

- Microcontrollers55 products

- Modules/Shield7575 products

- MOSFET / IGBT1414 products

- Power Supply2525 products

- Resistors130130 products

- Sensors5959 products

- SMD2828 products

- Switches1414 products

- Transistors6868 products

- Wire and Cables1212 products

- Hardware3232 products

- Hand Tools1414 products

- Hardware Accessories1414 products

- Printing22 products

- RC Plane and Drone99 products

- Robotic147147 products

- BO Motors1313 products

- General Purpose DC Motors2929 products

- Motor Drivers88 products

- Robotic Wheels & Tyres1414 products

- Servo Motor2727 products

- Stepper Motors88 products

- Synchronous Motor11 product

- Science Fair Project7070 products

- Final Year Ready Project Kit11 product

- STEM KIT2222 products

- E Books88 products

Leave a Reply

You must be logged in to post a comment.