Case Study: Reducing Errors in Weld Quality Control with LED Film Viewers

In the oil & gas, power, and fabrication industries, weld quality directly impacts safety and reliability. A single missed defect can lead to pipeline leaks, equipment failure, or costly rework. For decades, radiographic testing (RT) has been the gold standard for weld inspection, but the accuracy of defect detection depends heavily on the film viewer being used.

This case study highlights how LED radiography film viewers significantly reduce errors in weld quality control (QC) by delivering consistent brightness and high-density film evaluation.

The Challenge: Missed Defects in Weld Inspection

An NDT service provider in India performing pipeline weld inspections faced recurring issues:

Traditional fluorescent viewers lacked brightness uniformity.

Dark, high-density radiographs were difficult to evaluate.

Inspectors suffered from eye strain during long shifts.

Small cracks and porosity often went undetected until later rework.

These limitations led to false interpretations, project delays, and additional costs.

The Solution: Switching to LED Film Viewers

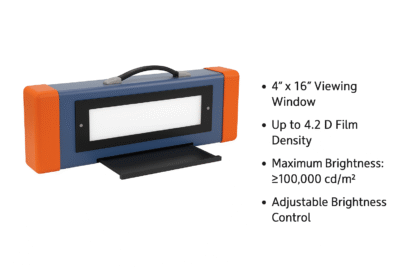

The company introduced LED-based radiography film viewers with:

High brightness (≥100,000 cd/m²) for clear visibility

Density rating up to 4.0 D for analyzing dark films

Adjustable brightness control for eye comfort and precision

Rugged design suitable for shop-floor and field use

Results: Improved Defect Detection and QC Reliability

After implementing LED viewers, the inspection team reported:

Higher Accuracy – Small defects such as cracks, inclusions, and porosity were detected more reliably.

Reduced Errors – Consistent brightness minimized false calls and missed defects.

Faster Inspections – Clearer viewing reduced inspection time per film.

Lower Rework Costs – Early detection prevented costly project delays.

Improved Inspector Comfort – Adjustable brightness reduced eye fatigue.

Conclusion

This case study proves that LED radiography film viewers are more than just a technology upgrade—they are a quality assurance tool. With proper brightness and density capability, they help NDT professionals in India improve defect detection, reduce errors, and ensure weld reliability.

For industries where weld quality is non-negotiable, investing in LED film viewers translates into safer operations, fewer reworks, and stronger compliance with standards.

👉 Call to Action

Looking for a reliable LED film viewer for weld quality control in India? Explore our industrial radiography film viewers, trusted for accurate defect detection and dependable performance. Shop Now at SmartXprokits