SMPS High-Efficiency Layout Tips for Prototypers

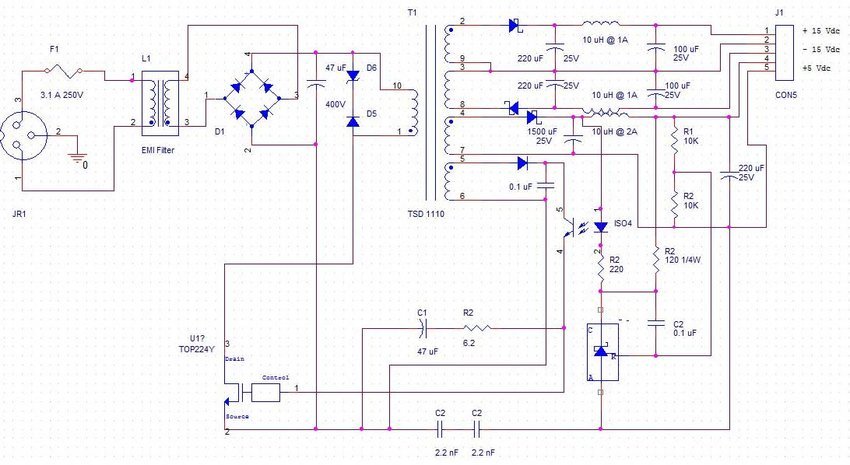

When designing a Switch Mode Power Supply (SMPS), layout is everything. Even with high-quality components, a poor PCB layout can cause overheating, EMI issues, and wasted power. Here’s how to get it right—especially if you’re a hobbyist or prototyper in India.

🔧 The Problem :

In SMPS circuits, fast switching can create noise and power losses. If your layout has long traces or poor grounding, efficiency drops fast. A clean, compact layout minimizes parasitic inductance and resistance, improving both performance and reliability.

✅The Solution :

Suppose you’re building a 5V 2A buck converter for a microcontroller. Placing the MOSFET, diode, and inductor close together reduces loop area, cutting EMI and boosting efficiency. Also, use a solid ground plane and short return paths.

🧮 Sample Calculation :

If your trace resistance is 0.05Ω and current is 2A,

Power loss = I²R = 2² × 0.05 = 0.2W.

Reducing trace resistance by better layout can cut this in half!

🛠️ Try These “Made in India” Components

Shop now at SmartXProKits.in

Support our work and India’s innovation—buy from our Make in India site!