Understanding SMPS Component Stress Analysis for Electronics Enthusiasts

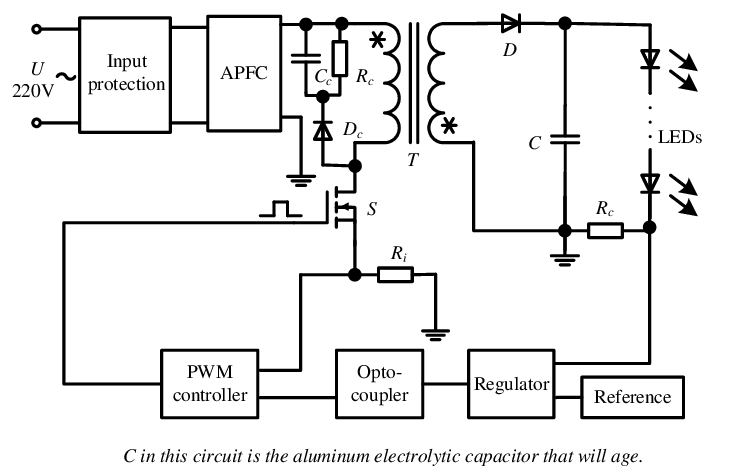

When building electronics projects, especially power supplies, understanding the stresses on SMPS (Switched-Mode Power Supply) components is crucial for reliable operation. SMPS designs, while efficient, involve components that are often under heavy stress due to high voltage, heat, and load conditions. Overstressed components can fail prematurely, ruining your project.

The Problem :

Imagine you’re building a power supply for your new LED strip project. After a few days of use, you notice flickering lights or, worse, a complete failure. This could be caused by overstressed components in the SMPS—like resistors or capacitors—overheating or failing due to excessive current or improper sizing.

The Solution :

The key to preventing component failure is to choose components with the right ratings for your project. Let’s say you’re using a capacitor. If your capacitor is rated for 25V and your power supply peaks at 30V, the capacitor might burst over time. To avoid this, always ensure your components have a safety margin—preferably a 20% higher rating than the expected voltage.

Practical Example :

For a simple current-limiting resistor, let’s say you need to limit current to 100mA in a 12V circuit. Using Ohm’s law:

Resistor Value = Voltage / Current = 12V / 0.1A = 120 ohms

Sample Calculation :

Make sure the resistor’s power rating can handle the power it dissipates. For a 120-ohm resistor carrying 100mA:

Power = Voltage x Current = 12V x 0.1A = 1.2 watts

Choose a resistor with at least a 1.5W rating for safety.

Product Suggestion :

For SMPS projects, choose high-quality components like MOSFETs and capacitors. These components are vital in ensuring smooth, reliable power delivery. Look for products that are Made in India, supporting local innovation and quality.

Shop now at [SmartXProKits] and get the best for your project. Support our work and India’s innovation—buy from our Make in India site!